KBR-1500 V2 Mixed Value Counter FAQ

Downloadable Documents

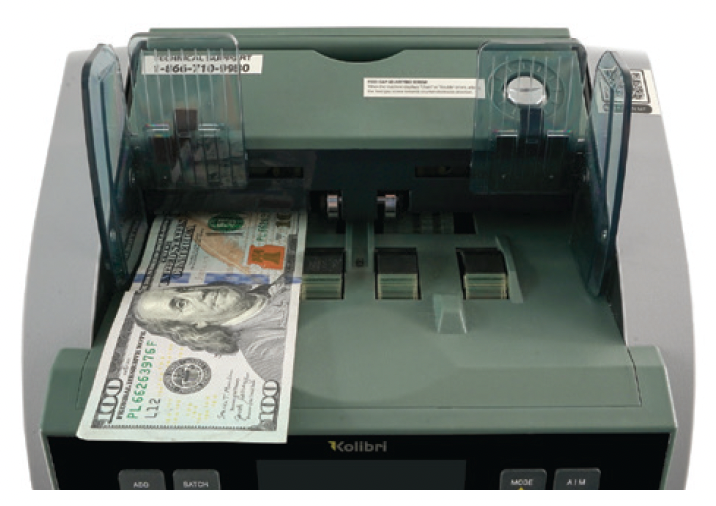

To avoid jams and ensure the proper operating speed of the machine, it is important to correctly load the hopper. Bills should be placed in a neat stack before being placed into the hopper.

Avoid counting bills that are wet, excessively dirty, folded, or curled. Bills such as these can cause the machine to malfunction. Foreign objects such as clips or bands may jam the internal mechanisms of the unit, causing mechanical failure.

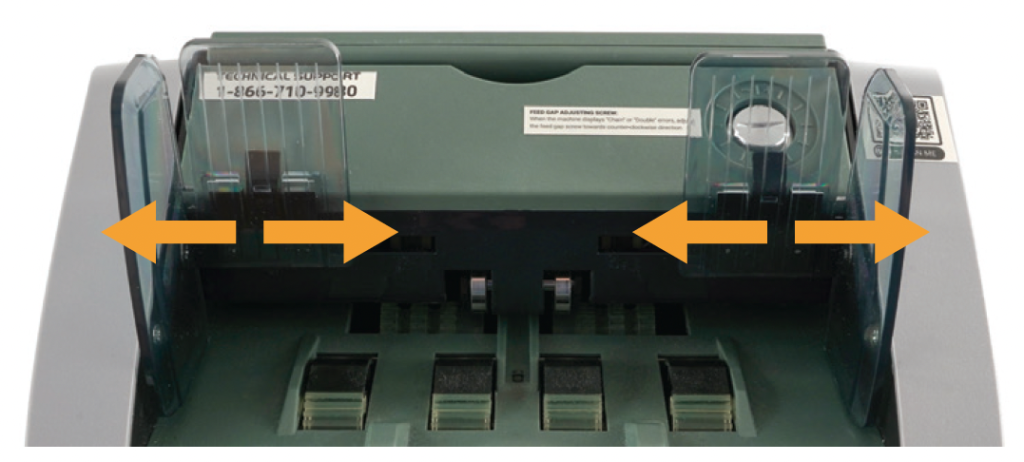

Adjust the hopper bill guides to a size slightly wider than the width of the bills. This will help to correctly situate the bills in the hopper and ensure smooth bill feeding.

The unit has fast moving parts and may be hazardous if fingers, hair, clothes, etc. get near the fast moving parts. Please be mindful of loose clothes, hair or fingers coming too close to the fast moving parts.

In order to properly load bills into your machine please follow the instructions and diagrams below:

- Make a Stack – Correct or remove bills that are severely wrinkled, damaged or folded. Square the bill stack.

- Load the Stack

- Feed the Bills

ATTENTION: The KBR-1500 should always be turned off and disconnected from its power cord before cleaning. DO NOT use solvents to clean the machine.

Most operational problems can be avoided by regular care and preventative maintenance. Taking regular care of the KBR-1500 will significantly increase its lifetime.

To avoid problems, make sure there are no metal clips or rubber bands in the bills being counted. Be sure to follow the proper procedure for loading the hopper, refer to section 2.2 Hopper Loading Procedure of the KBR-1500 V2 user manual.

For best results, it is recommended to use an air duster and a soft bristle brush to remove any dust or debris from the interior of the unit. When not using the machine for an extended period, cover it with the provided dust cover to prevent dust from settling inside.

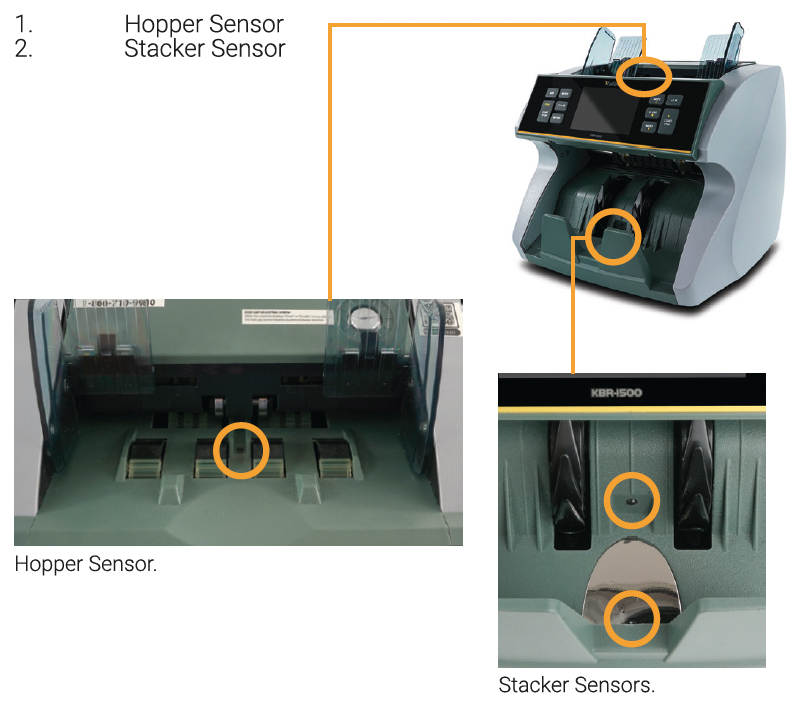

All parts of the KBR-1500 need daily care and cleaning. Pay close attention to the sensors, which are delicate components. If any dust or other foreign matter adheres to the sensors, it may cause various problems during operation of the machine.

NOTE: The KBR-1500, like all other discriminators on the market with integrated detectors, cannot 100% guarantee a counted bill to be genuine or counterfeit. There are several reasons a genuine bill may be recognized as counterfeit, or vice versa.

Possible reasons include direct sunlight exposure, worn bills, excessively dirty bills, or highly advanced counterfeiting techniques used to produce the bill. Separate equipment may be required to definitively determine whether or not a bill is counterfeit.

Error Message | Cause | Solution |

SUSPECT UV NOTE | Suspect bill detected by ultraviolet detection or there is UV detection issue.

| Remove the top bill from the stacker. The bill is no added to the count. Press START to continue.

|

SUSPECT NOTE MG | Suspect bill detected by magnetic detection or there is MG detection issue.

|

|

SUSPECT NOTE IR | Suspect bill detected by infrared detection or there is IR detection issue.

|

|

SUSPECT NOTE IMAGE | Image of the bill is not genuine.

|

|

SUSPECT NOTE ID | Image of the bill is not recognized.

|

|

SUSPECT NOTE SIZE | The size of the bill is not genuine.

| Remove the top bill from the stacker and make sure it is full-size. This bill is not added to the count. |

Error Message | Cause | Solution |

SUSPECT NOTE DENOMINATION | Denomination of the bill doesn’t match the first bill in the stacker.

| Remove the top bill from the stacker. The bill is no added to the count. Press START to continue.

|

WARNING DOUBLE | The last counted bill is a double note or had double detection issue.

| Check if the last notes in the stacker are stuck together. Remove all notes from the stacker. The total count will be reset. Press START to recount. |

WARNING CHAIN | Two or more bills passed as one.

| Check if the last notes in the stacker are stuck together. Remove all notes from the stacker. The total count will be reset. Press START to recount. |

WARNING HALF | The last bill counted doesn’t confirm the size, rejected bill might be torn or folded.

| Check if the last notes in the stacker are full-size bills. Remove all notes from the stacker. The total count will be reset. Press START to recount. |

ERROR | IR sensors issue

| Proceed with the Calibration procedure. Refer to Section 6.3 of the user manual. |

Problem Description | Cause/Action |

KBR-1500 does not turn on. | Ensure the power cord is connected properly. Check the fuse in the fuse compartment and replace if necessary. Contact Kolibri’s technical service center if the issue persists.

|

KBR-1500 fails to detect counterfeit notes.

| The sensors may have collected dust. Refer to Section 6.1 Maintenance for location of sensors.

|

Sometimes, during the transportation or shipment of the unit, the adjustment of the feed mechanism may loosen. This can also happen during normal wear or tear and can lead to DOUBLE/CHAIN errors. The feed gap is the actual height of the bill feed path and should be tuned to just about the thickness of a single bill. If the feed gap is too wide, the user may experience a high amount of DOUBLE/CHAIN errors which are caused by more than one bill entering the scanning path at one time. If the feed gap is too tight, the unit may not be able to pass bills into the scanning path or catch on bills and tear them.

The following steps are the procedure for adjusting the feed gap:

- Ensure the machine is turned off.

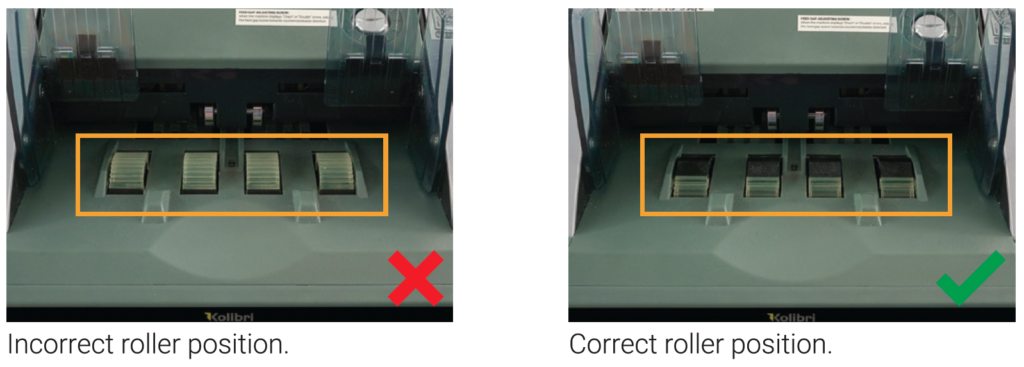

- Position the rollers so that only two teeth in front are visible. This can be done by manually turning the rollers until only two teeth are showing and the smooth section of the rollers mainly is visible (see the images below).

- Place one bill that is crisp and rigid enough to prevent bending during the adjustment procedure. Place the bill lengthwise either to the right or left side of the hopper (See image below).

Guide the bill between the inner rollers during this step; moderate resistance should be felt as the bill is moved back and forth through these rollers. In other words, the gap between these rollers should be wide enough to pass just one bill per count, but narrow enough to feel a slight tension or friction when pulling the bill out

To adjust the feed gap, use the instructions below to turn the adjustment screw on the top of the unit:

a) Adjust the knob, slight turn at a time, and then retest.

b) If the bill feels too loose, tighten the feed gap by turning the adjustment screw counterclockwise.

c) If the resistance against the bill feels too strong, loosen the gap by turning the screw clockwise.

IMPORTANT NOTE:

The Kolibri KBR-1500 feed gap adjustment can be sensitive during adjustments. Do not overturn each adjustment or you may overshoot the optimum gap. We recommend testing with a stack of bills after each adjustment turn.

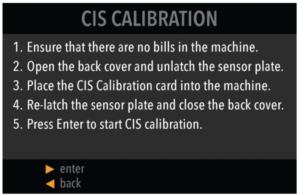

The Ultraviolet (UV) and Infrared (IR) sensors of the unit are calibrated properly from the factory. With regular, basic use, the sensor’s sensitivity decreases which can lead to ID errors. To resolve this issue, the unit can be re-calibrated using the white calibration card that comes with the unit.

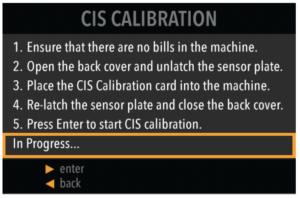

Please follow the steps below to calibrate the sensor:

- Ensure the machine is turned ON.

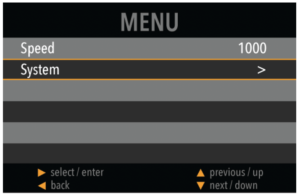

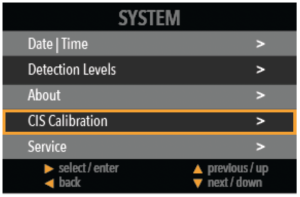

- Press the MENU button, move down, and select System when in System, select CIS CALIBRATION when in CIS CALIBRATION the instruction will be written on the screen.

- Then turn the machine backside front.

- Pull the back door handle to get access to sensor blocks.

When inside, push the metal latch down to get access to the upper and lower sensor block with CIS sensors.

Put provided white calibration card between two sensor blocks. Bring the lower sensor block

back to its initial position by pushing the metal latch down and lifting the lower sensor block.

Make sure the lower sensor block is hooked back properly.

- Carefully proceed to close the back door with the calibration card inside the machine.

- Turn the KBR-1500 face side to yourself and press the START/STOP button to start the calibration process.

- Calibration will begin and the calibration screen will display the message “In Progress”.

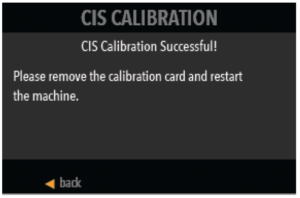

- When calibration is done “CIS Calibration Successful!” message must be displayed on the screen. The white calibration card should be removed and the KBR 1500 must be restarted.

- The calibration is done.

- If ERROR message displays “CIS Calibration Failed” the calibration card must be readjusted and placed exactly on top of the sensors and steps from 3 to 6 must be repeated.